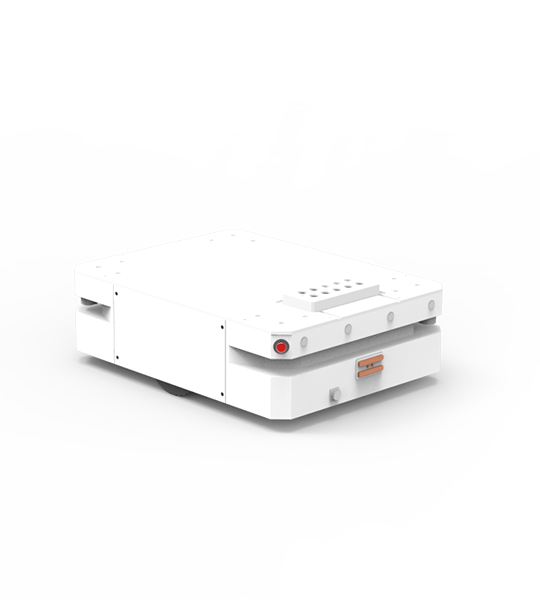

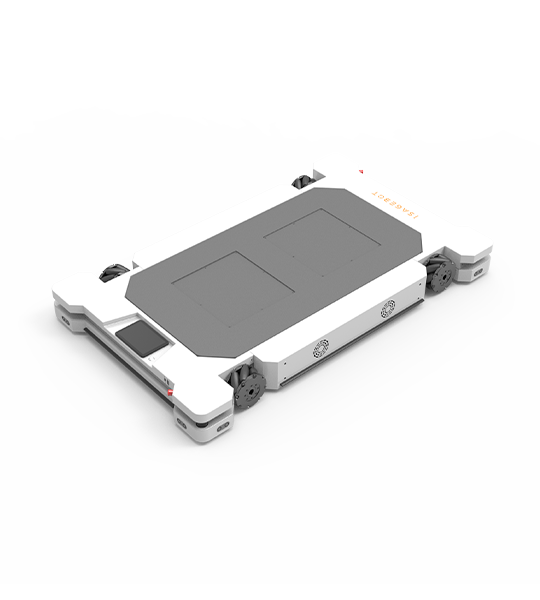

iSAGEBOT offers professional end-to-end solutions for production line to assist enterprises in automating workshop process. This reduces labor costs and safety hazards while effectively enhancing factory production and transferation efficiency.

Intelligent Manufacturing

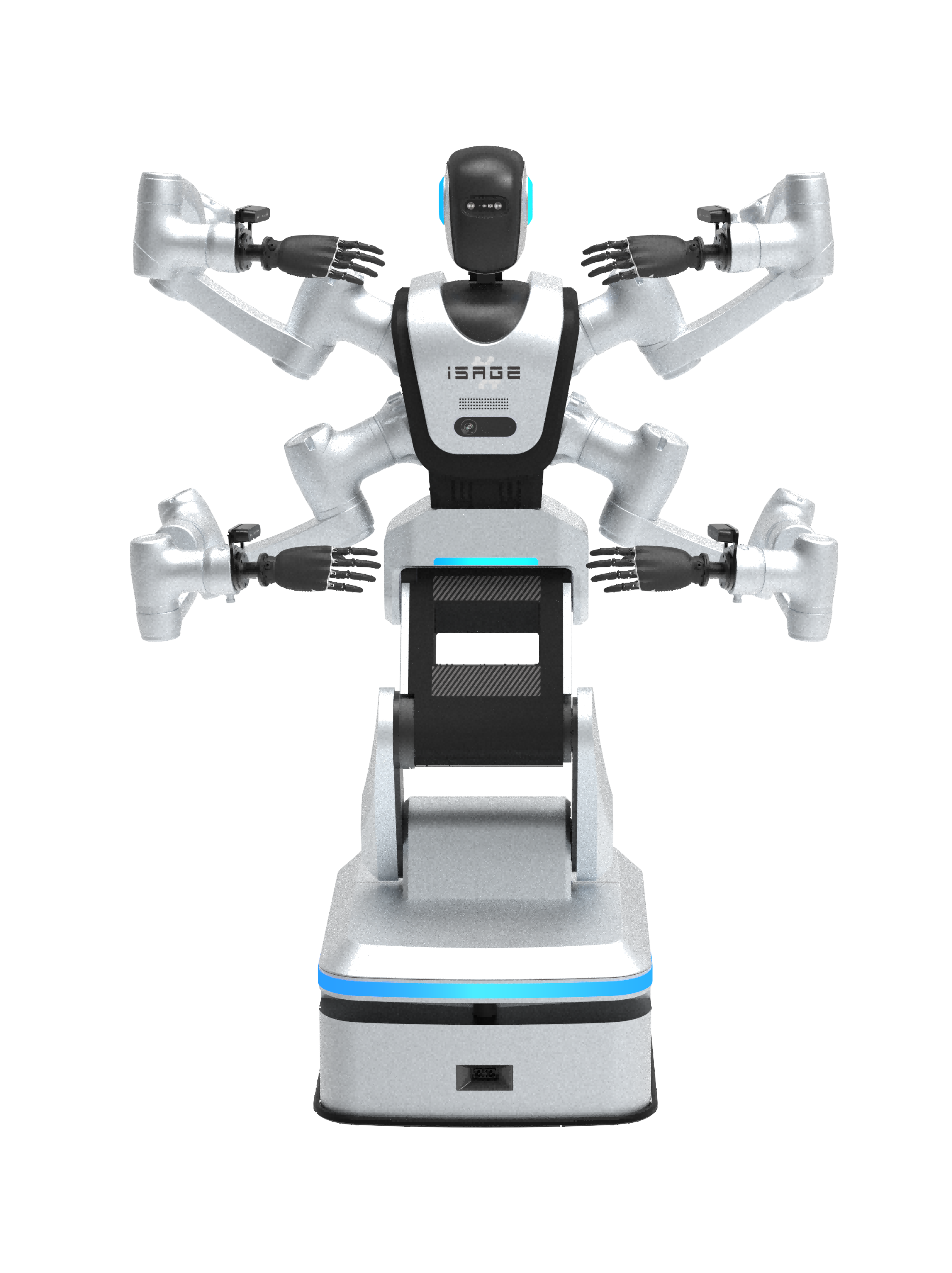

- Hand-Eyes-Feet-Brain

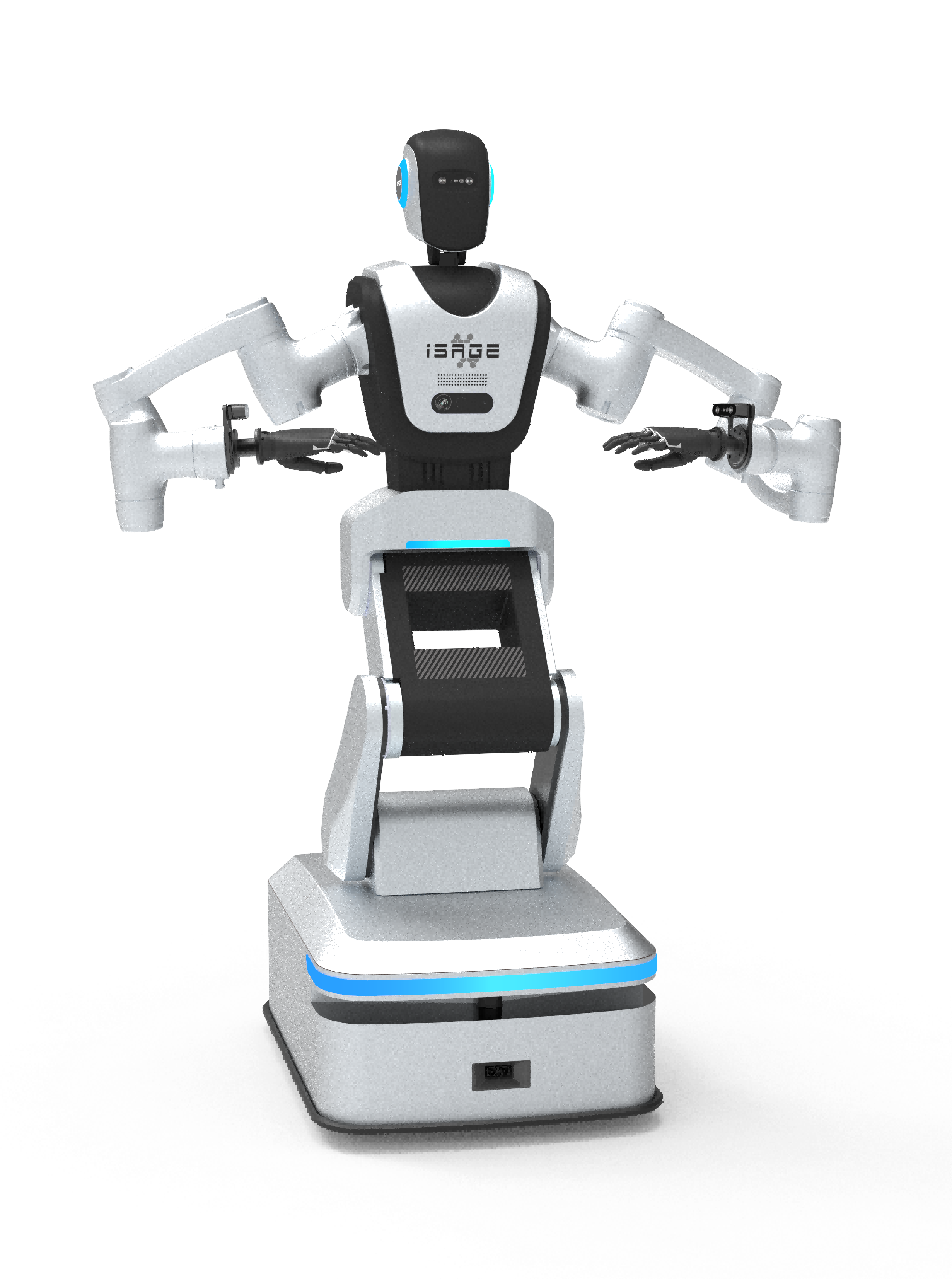

- Eyes-Feet-Brain