For the rapid expansion and increased diversity of new energy industry, iSAGEBOT offers full-lifecycle solutions to achieve lean and intelligent management of the entire manufacturing process, ensuring efficient coordination between production and logistics.

Intelligent Manufacturing

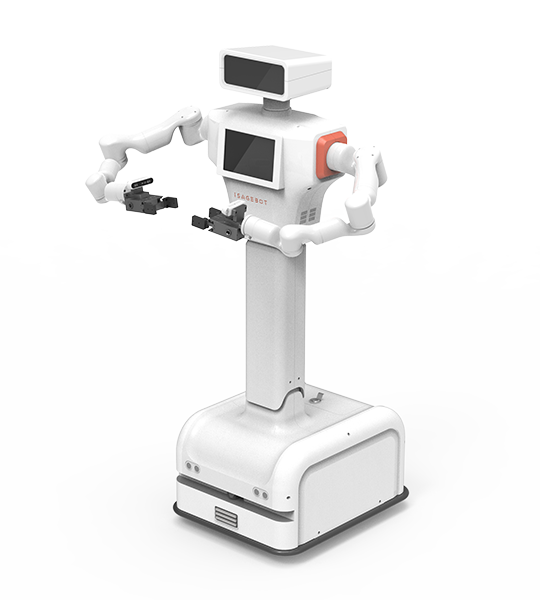

- Hand-Eyes-Feet-Brain

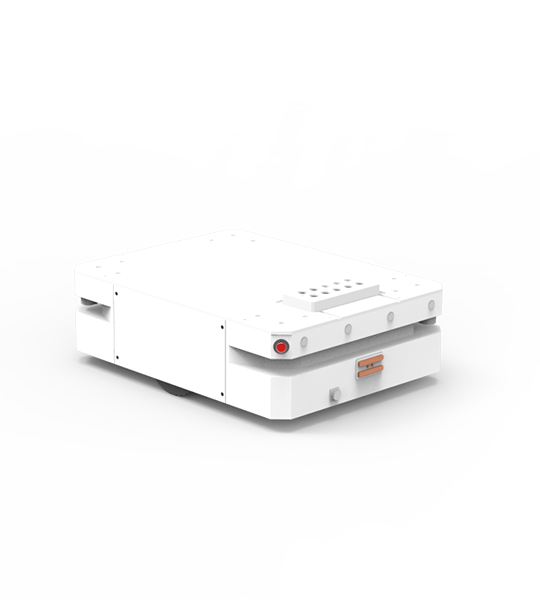

- Eyes-Feet-Brain

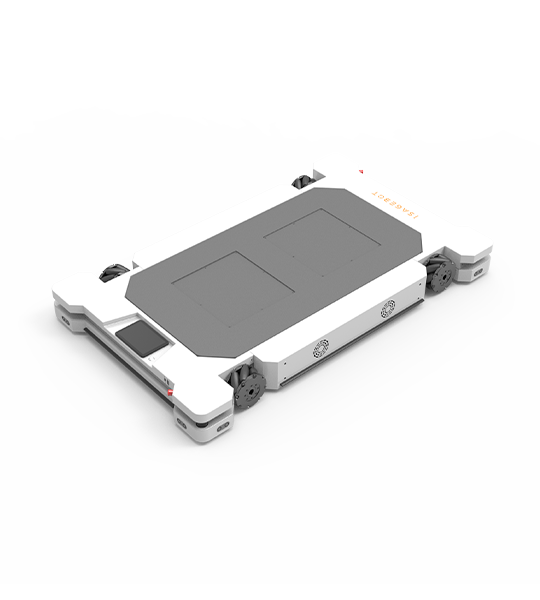

- Eyes-Hands-Brain