Food and beverage industry demands precision, cleanliness, and quality in manufacturing. iSAGEBOT offers a full-supply-chain solution, integrating transfer, packaging, inspection, loading, and palletizing to streamline production scenaios, helping enterprises reduce costs and improve efficiency.

Intelligent Manufacturing

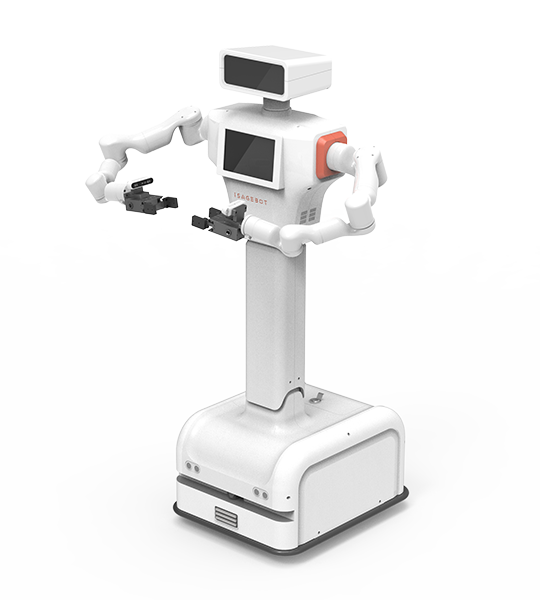

- Hand-Eyes-Feet-Brain

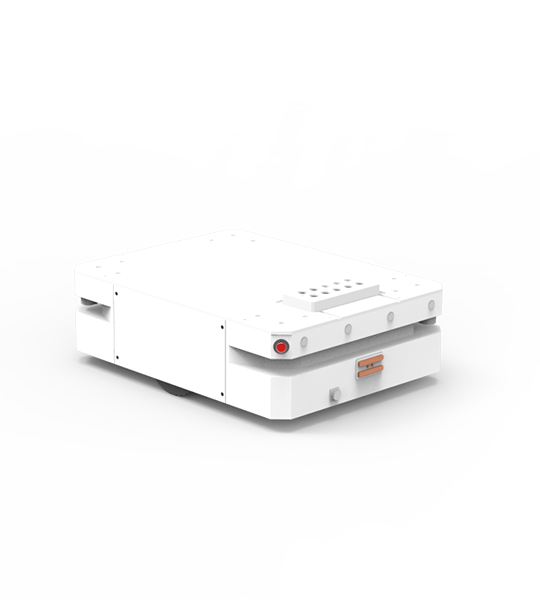

- Eyes-Feet-Brain

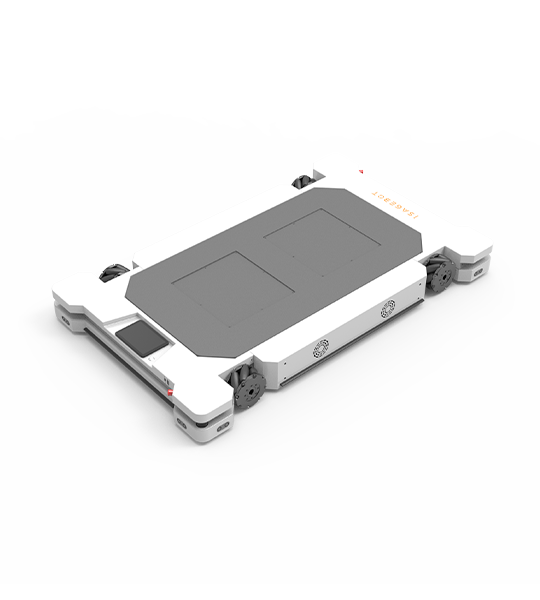

- Eyes-Hands-Brain