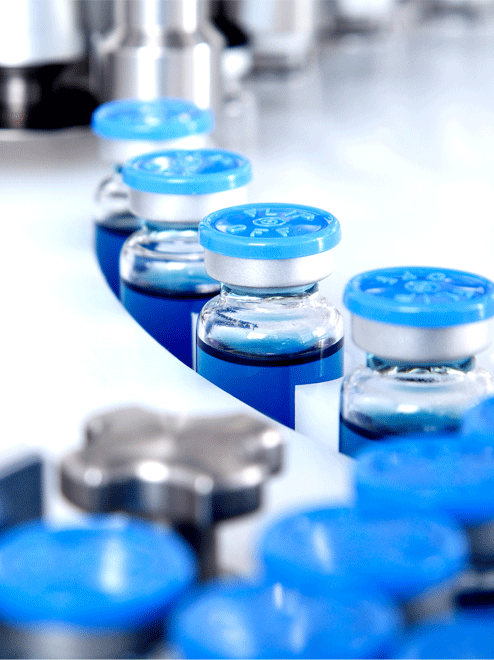

With sophisticated project experience and comprehensive product series, iSAGEBOT provides “turn-key” solutions for various processes in bio-pharmacial production. From manufacturing, transferring, picking&placing to testing and inspecting, iSAGEBOT c

Intelligent Manufacturing

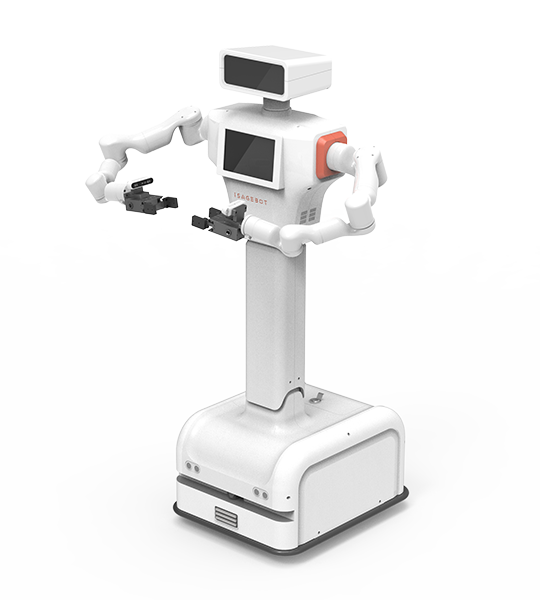

- Hand-Eyes-Feet-Brain

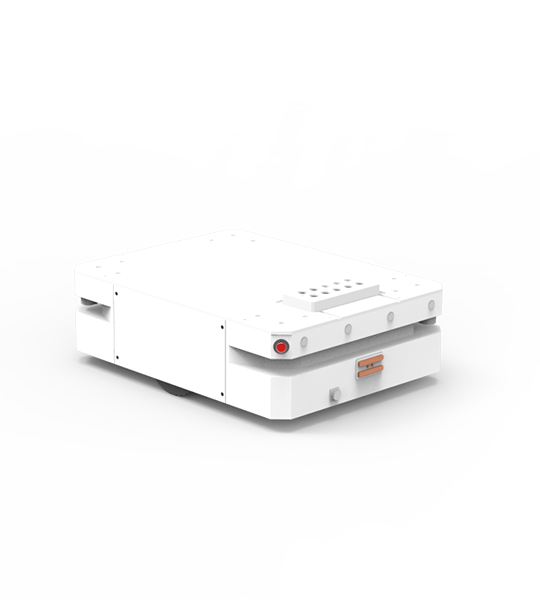

- Eyes-Feet-Brain

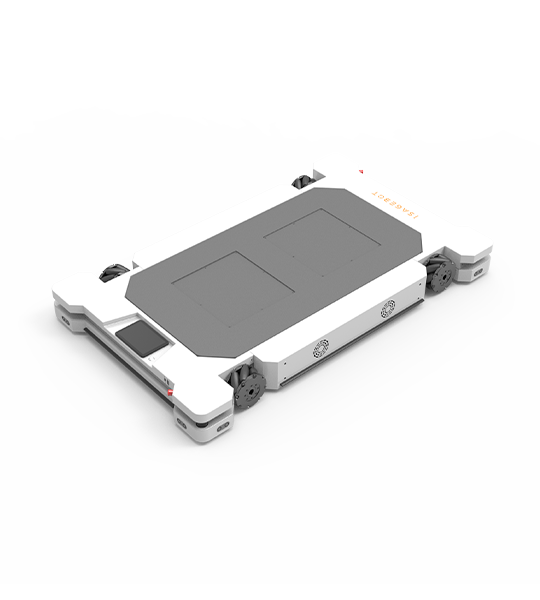

- Eyes-Hands-Brain